- Home

- Services

- Special Technologies

- Bored piles

Bored piles

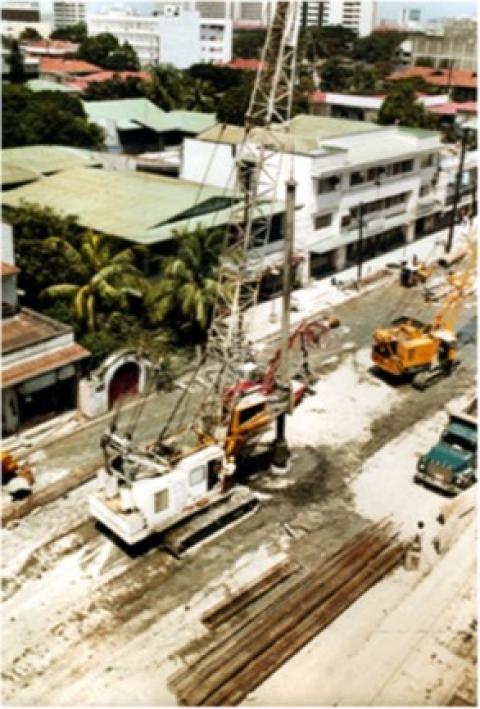

ABSTRACT: Bored Piles are reinforced concrete cylindrical structures cast in place in a drilled / bored hole. They are the most versatile types of deep foundation due to their adaptability to many kinds of ground conditions whether in land or offshore or in river-beds, as shown in the pictures. Bored piles diameters range from 600mm to 5,000mm, with depths that can reach down to 100 meters. Bored piles are installed by first removing the soil by a drilling process and then constructing the pile by placing reinforcing bars cages and concrete in the hole. The simplest form of construction consists of drilling an unlined or unprotected hole and filling it with concrete. Complications that may arise such as difficult ground conditions and the presence of ground water have led to the development of special drilling technologies.

BORED PILES are cast in place cylindrical piles excavated either by use of rotary equipment operated augers , buckets, under static drilling fluid or large drill bit (for hard rock) with reverse circulation, with chisel grab and casing oscillator for bouldery ground, with large diameter DTH hammers and compressed air (drilled piles), among others.

Most common large diameter bored piles, are installed through an overburden of cohesive or cohesionless soil strata, with or without water table, down to firmer ground, to achieve the design bearing capacity by skin friction, base bearing or both, to serve as foundation piles for residential, commercial, institutional buildings, industrial complexes or infrastructures.

Bored piles installed in common soil with the presence of water table, generally require the use of a short temporary steel casing and a drilling fluid as static suspension to provide support to the surrounding soil while excavating the pile and until complete backfill of the pile excavation with concrete, in order to prevent cave-in of the excavation and destabilizing the surrounding soil formation.

The preparation and handling by most effective drilling fluid, Bentonite Mud, is a sophisticated technology by itself and requires a complete set up of dedicated equipment and (basic) field laboratory.

Diameters of bored piles range from 0.6 meter to 4.0 m meters, likewise length can range from few meter to sixty or more meters, depending upon design loads and soil parameters.

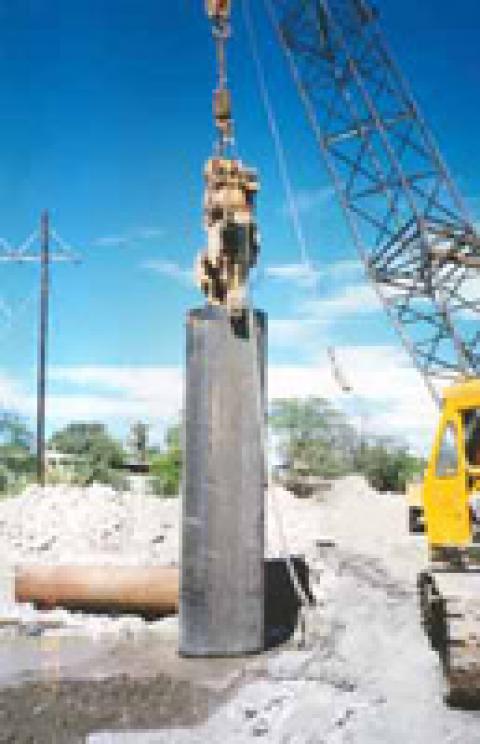

Bored piles can be heavily reinforced if required by design, rebar cages usually are prefabricated in segments with length and weight depending upon available commercial lengths of rebars and available lifting equipment. Splicing of rebar cages can be done by lap splice, welded lap splice or mechanical threaded couplers. Casting is done by pouring concrete with the design strength and slump as required, through watertight segmental Tremie Pipes, starting from the pile bottom and letting the tremie pipe bottom-end remain at least 3 meters submerged in concrete until the completion of pouring, to guarantee the pile continuity and the final good quality of the concrete cast.

Drilling fluids, if needed, can be water, a suspension of bentonite (bentonite mud), a suspension of polymers, depending upon soil type, soil conditions, presence and elevation of water table, chemical properties of water table (Ph & Salinity).

Steel casings can be temporary, in which case the wall thickness is usually big enough to allow many uses, are provided with collars for easy handling by vibro-hammers and diameter slightly larger than bored piles’ nominal diameter, in order to allow easy passage of drilling tools. Permanent casings, if needed, are sacrificial casings and as such the wall thickness is as small as allowed by the need to drive the casing through the ground.

Bored piles are commonly employed for bridge foundations, on land and water, because the versatility of bored piles design and execution allows the construction of practically any needed diameter, including the very large diameters, and the

pile reinforcement can be provided as heavy as needed by seismic design and the codes (it is not uncommon to have double wall rebar cages in order to accommodate all the needed bars, however care shall be taken to leave sufficient space between bars for concrete to flow through).

Bored piles are also used to form retaining walls (see Pile Wall), as contiguous pile wall or secant pile wall or aligned pile wall, with or without post tensioned soil anchors as tie back .

Bored piles testing is usually done in two (2) stages, first stage testing to verify design assumptions and achievable design load , is done before starting the execution of the working piles: test piles are installed in the proposed construction area, as per design, and tested, first for integrity and continuity by P.I.T. (Pile Integrity Test) then for load bearing capacity , either by Static Load Test or by Dynamic Load Test PDA, (Pile Dynamic Analysis). At times the Designer might require a Pull-out test and a lateral load test.

Once the design pile capacity has been confirmed, Bored Piles construction for the working piles starts and quality control is then done on representative piles. Quality Control consists of testing the material used for the bored piles, i.e. reinforcing bars and concrete, then testing of the piles at random with PIT and PDA, and predetermined piles with static pile load test. Predetermined piles can also be tested using the cross-hole ultrasonic test, by inserting instruments through vertical pipes installed within the reinforcing steel cage all throughout the bored pile length.